Qualcomm’s 2nm Chip Breakthrough Signals India’s Leap into Global Semiconductor Leadership

Qualcomm’s successful 2nm chip tape-out led by Indian engineering teams marks a turning point in India’s semiconductor journey, positioning the country as a global hub for advanced chip architecture under Semicon 2.0.

In February 2026, Qualcomm claimed to have successfully taped out its advanced 2-nanometre (2nm) chip design- again a feat that has been facilitated by its engineering centres in Bengaluru, Chennai and Hyderabad. The breakthrough is a structural change in addition to a technical milestone: India is not only contributing to the global semiconductor innovation anymore, but it is now making it at the very core of the architectural design.

Back Office to Brain Trust: India Takes Design Ownership

The most significant outcome of the announcement made by Qualcomm is the ownership of engineering. The 2nm chip was developed as an end to end project in India, which involved the definition of customer products, system architecture, physical design and final verification. This amount of responsibility was traditionally vested in the US, Taiwan or some sections of Europe. More importantly, this trend undermines the old-established vision of India as a back-office destination, where testing or verification is performed. Rather, Indian engineers are currently stipulating the way that next-generation chips are being conceived what they address, how effectively they are utilised, and the locations they will be utilised. This transformation has not occurred at once, it is a see of almost 20 years years of design capacity and ecosystem maturity.

The 2nm Matters: Power, Performance, and Scale

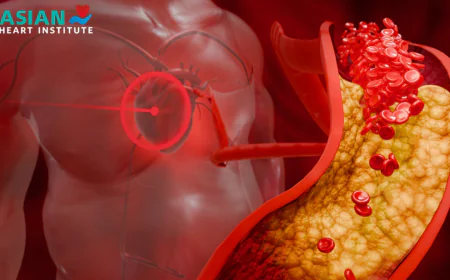

The figures at technology level are mind boggling. The 2nm chip die packs between 20 and 30 billion transistors and merges the high performance CPU and the graphics processor architecture on the same platform. The transition to 2nm allows a maximum 45 percent reduction in energy usage over previous nodes- a game changer in a time when AI workloads and power constitute the focus. In practise, this efficiency will drive the next generation of AI servers, high-end smartphones, and IoT ecosystems, where the performance-per-watt is a requisite. Between the data centres that have a hard time covering the heat and power bills and the edge devices that require more battery life; 2nm is not an incremental city, it is a base city. India as a facilitator of this jump puts it in the strategic tier of technology competition in the world.

Semicon 2.0 and Road to Fabrication Sovereignty

Union Minister Ashwini Vaishnaw has placed this accomplishment in the larger semiconductor roadmap of India commonly known as Semicon 2.0. The plan is to make India shun off legacy nodes such as 28nm and 7nm, and eventually, advanced node such as 2nm fabrication. Although the chips of Qualcomm are yet being produced in foreign high-technology foundries, the success of the design confirms the availability of India in the global semiconductor value chain under the India Semiconductor Mission. This dual effort by the government, whereby more than 85,000 engineers are being trained and hundreds of universities are equipped with advanced EDA tools, augurs well of a long-term effort and not a symbolic one.

Fabrication of design leadership is a half-baked win, though it is the more difficult half of the challenge. Design ecosystems are decades old, fabrication plants can be capitalised. The 2nm tape-out presented by Qualcomm shows that India has made the toughest step. The second test is whether the design dominance can be transformed into full-spectrum semiconductor sovereignty by means of policy stability, talent retention and supply-chain integration.